Bakery Processing Dough Sheeting Production Line

Equipment Advantages

Equipment Introduction-Bakery Processing Dough Sheeting Production Line

Intelligent control system, which can realize automatic adjustment of dough thickness and speed (optional)

Calendering dough sheet, continuous and stable production without interruption, high efficiency and labor saving.

Modular combination design is adopted to realize diversified production through flexible and convenient combination.

The whole line adopts high-quality parts, and the design can be washed easily.

The low-stress calendering system can calender dough band maintaining complete internal structure and relaxation.

Contact us for pastry lamination line for your bakery business!

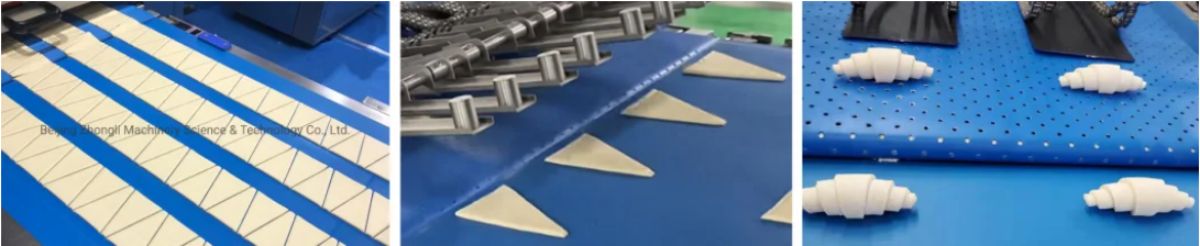

End Food Product Range: pastry and laminated bread, sourdough bread, croissants, egg tarts, pies, durian custard pie, char siew sou,galette,square cookies, puff pastry, palmier and other uniquely shaped puff pastry.

Product details

Conveyor Belt Working Width

| 600mm | 800mm |

| 1000mm | 1200mm |

Capacity :12000-24000pcs per hour

Dough Band Calendering

The dough band forming system adopts a low stress calendering processing method to gently process the dough band into the required width and thickness, so as not to damage the organizational structure of the dough band and ensure that the dough softer.

Dough Resting and Cooling System

The dough band is transported to the low-temperature relaxation tunnel, which is relaxed as required according to the process requirements of each customer. The low-temperature tunnel is equipped with an anti condensation device, so that the dough will not be dried and cracked without direct blowing.

Fat Pump System

The professionally designed fat pump machine is the very important machine for pastry bakery machine , when the dough belt is transported to the fat outlet nozzle of the fat exitor, the grease is extruded and laid on the dough belt in the form of a thin fat belt at the same time. The dough belt with grease turns the dough belt on both sides to the grease through the flanging device, wraps the grease, and completes the thin oil action. The fat outlet nozzle can produce uniform grease of a given width and thickness according to the customer's requirements, so as to ensure no accumulation of fat.

Fat Wrap Up

The professionally designed fat pump machine is the very important machine for pastry bakery machine , when the dough belt is transported to the fat outlet nozzle of the fat exitor, the grease is extruded and laid on the dough belt in the form of a thin fat belt at the same time. The dough belt with grease turns the dough belt on both sides to the grease through the flanging device, wraps the grease, and completes the thin oil action. The fat outlet nozzle can produce uniform grease of a given width and thickness according to the customer's requirements, so as to ensure no accumulation of fat.

Satellite Rolling

The satellite wheel type dough rolling tower gently handles the dough belt, evenly spreads the grease and dough belt, and the dough belt is repeatedly rolled to form a dough belt with the width and thickness set to the preset value, which is sent to the dough belt folding system, also known as the pastry opening system in the industry

Folding 1

The folding method of cutting the stack can evenly handle the grease at any position of the dough strip to the greatest extent, which is more friendly to high-quality crisp dough, and the number of folding layers can be set according to customer needs.

Folding 2

The folding method of cutting the stack can evenly handle the grease at any position of the dough strip to the greatest extent, which is more friendly to high-quality crisp dough, and the number of folding layers can be set according to customer needs.

Gauging Roller

The width and thickness of the dough belt that has been extended through multiple rolling passes are determined according to the needs of the rolling dough. The final product thickness required by the travel is determined according to the production capacity requirements. The width of the rolling dough is determined according to the production capacity requirements. We can provide 680-1280mm equipment width to meet the production capacity requirements of different customers.

Dis-cutter

After rolling and folding for many times, when the loosened pastry dough belt runs to the dough forming section according to the required thickness and width, it is divided into several narrow belts by the longitudinal cutting mechanism for filling or rolling and folding

Palmier Forming Process

Croissant Forming Process