Full Automatic Steamed Stuffed Bun/Steamed Bread Production Line

Product Features

•Full automatic steamed bun production line includes dough sheeting forming part and can be connected •with proofing machine to realize full automatic production process.

•The line designed for large industrial food factories . Make sure rounder shape is consistent by dough belt forming way and encrusting cutter.

•Excellemt processing results thanks to the use of quality stainless steel

•Capacity :20000-60000pcs per hour

ADVANTAGES

-High Stable Pastry Make Up Line with Optional Oven & Cooling

-Turn-key / Integrated Solution for Your Production

-Product Range: Croissant ,mesh pasty bread ,Etc.

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

Product Specification

| Equipment Size | 22000*5300*2000MM |

| Equipment Power | 27.7KW |

| Equipment Weight | 5560kg |

| Equipment Material | 304 Stainless Steel |

| Equipment Voltage | 380V/220V |

Product Show

ZL-1608 bread production line adopts modular combination design. Through flexible and convenient combination, it can improve the competitiveness and meet the production needs of various products. A full set of Siemens control system is adopted, which is easy to operate and stable in performance.

This production line adopts automatic control technology.

1.Improve the safety of production process.

2.Improve productivity.

3.Ensure product quality.

4.Reduce the consumption of raw materials and energy in the production process.

5.Save labor costs, replace labor with machinery, and reduce labor volume.

6.Diversified production can be carried out, and our company can provide upgrading and transformation according to the situation.

7.It is controlled by PLC.

Equipment capacity: 1.0T-1.5T/H

Product size: cut 25mm-120mm according to product requirements

Product weight: knead 30g-180g according to product requirement

The dough dividing machine is matched with the dough pressing machine, which can reduce the labor and manpower and automatically divide the dough.

-Dough Hopper

The mixed dough is poured into the feeding hopper of the Danish bakery machine through the elevator, and the single feeding weight is designed according to the production capacity of the production line, so as to ensure that the colleagues with constant processing of the dough do not wait too long for the dough.

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

-Dough Forming

The dough belt forming system adopts a low stress processing method to gently process the dough belt into the required width and thickness, so as not to damage the organizational structure of the dough belt and ensure that the dough softer.

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

-Satellite rolling

The satellite wheel type dough rolling tower gently handles the dough belt, evenly spreads the grease and dough belt, and the dough belt is repeatedly rolled to form a dough belt with the width and thickness set to the preset value, which is sent to the dough belt folding system, also known as the pastry opening system in the industry

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

-Gauging roller

The width and thickness of the dough belt that has been extended through multiple rolling passes are determined according to the needs of the rolling dough. The final product thickness required by the travel is determined according to the production capacity requirements. The width of the rolling dough is determined according to the production capacity requirements. We can provide 680-1280mm equipment width to meet the production capacity requirements of different customers.

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

-Separator belt

After rolling and folding for many times, when the loosened pastry dough belt runs to the dough forming section according to the required thickness and width, it is divided into several narrow belts by the longitudinal cutting mechanism for filling or rolling.

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

-Rolling To Cylinder

When making ramen bags, chocolate bags, or filling roll products, use the roll mechanism

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

-Rolling To Cylinder

When making ramen bags, chocolate bags, or filling roll products, use the roll mechanism

Knead Machine Bread Sheeting Dough Making Bun and Steamed Bun/Jam Bun

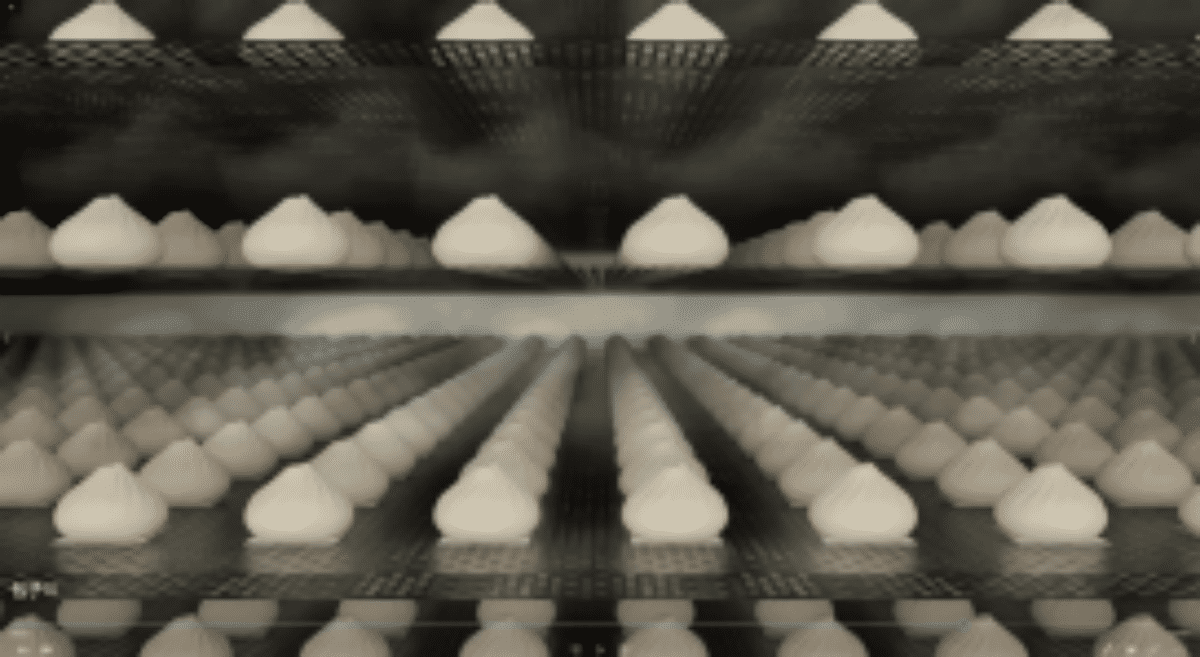

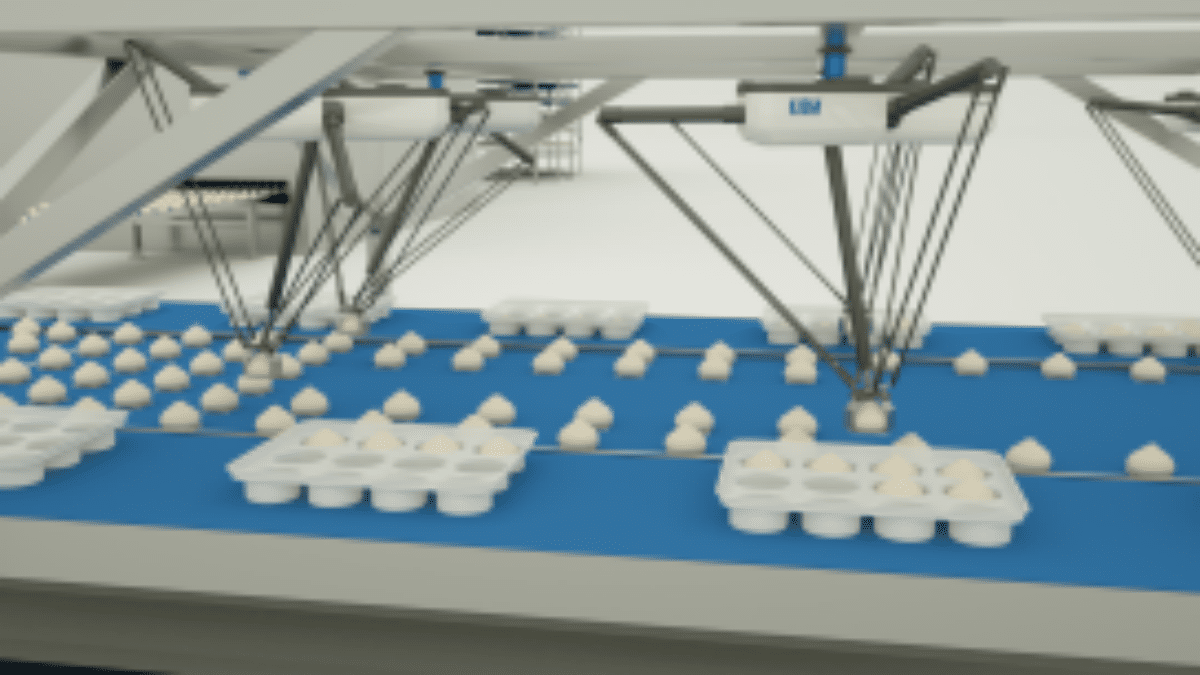

-Tray Arrangment

The fully automatic tray arrangement device can be made according to the size of the customer's tray, and the number of products can be placed according to the production capacity demand and the emerging demand. After years of technical improvement, we can place products across trays.

Product Show

Operate dertials