Lamination Puff Pastry Stick Production Line

ADVANTAGES:

-High Stable Pastry Make Up Line with Optional Oven & Cooling

-Turn-key / Integrated Solution for Your Production

-Product Range: Croissant ,mesh pasty bread ,Etc.

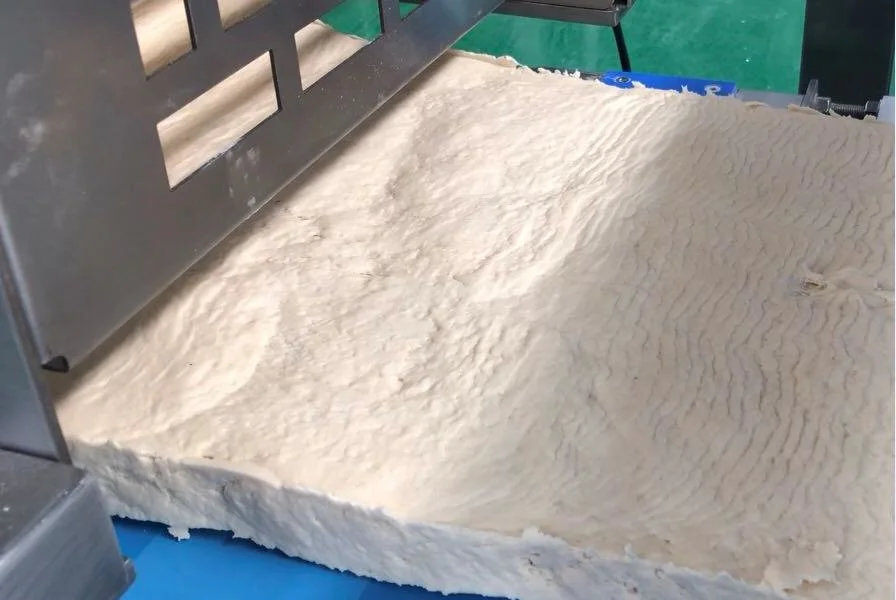

-Dough Hopper

The mixed dough is poured into the feeding hopper of the Danish bakery machine through the elevator, and the single feeding weight is designed according to the production capacity of the production line, so as to ensure that the colleagues with constant processing of the dough do not wait too long for the dough.

-Dough Forming

The dough belt forming system adopts a low stress processing method to gently process the dough belt into the required width and thickness, so as not to damage the organizational structure of the dough belt and ensure that the dough softer.

-Satellite rolling

The satellite wheel type dough rolling tower gently handles the dough belt, evenly spreads the grease and dough belt, and the dough belt is repeatedly rolled to form a dough belt with the width and thickness set to the preset value, which is sent to the dough belt folding system, also known as the pastry opening system in the industry.

-Fat pump system

The professionally designed fat pump machine is the very important machine for pastry bakery machine , when the dough belt is transported to the fat outlet nozzle of the fat exitor, the grease is extruded and laid on the dough belt in the form of a thin fat belt at the same time.

-Fat folding hand

The dough belt with grease turns the dough belt on both sides to the grease through the flanging device, wraps the grease, and completes the thin oil action. The fat outlet nozzle can produce uniform grease of a given width and thickness according to the customer’s requirements, so as to ensure no accumulation of fat.

-Satellite rolling

The satellite wheel type dough rolling tower gently handles the dough belt, evenly spreads the grease and dough belt, and the dough belt is repeatedly rolled to form a dough belt with the width and thickness set to the preset value, which is sent to the dough belt folding system, also known as the pastry opening system in the industry

Folding 1

The folding method of cutting the stack can evenly handle the grease at any position of the dough strip to the greatest extent, which is more friendly to high-quality crisp dough, and the number of folding layers can be set according to customer needs.

-Guillotine

Separator sheeting dough line running to Guillotine device ,been to cut to required length ,then the pulling belt will put the cut dough square on turning 90 degrees belt .

Folding 2

The folding method of cutting the stack can evenly handle the grease at any position of the dough strip to the greatest extent, which is more friendly to high-quality crisp dough, and the number of folding layers can be set according to customer needs.

-Weight roller

The self weight pressing roller gently taps the dough belt to help open the crispy pastry layer in the folded area.

-Satellite rolling

The satellite wheel type dough rolling tower gently handles the dough belt, evenly spreads the grease and dough belt, and the dough belt is repeatedly rolled to form a dough belt with the width and thickness set to the preset value, which is sent to the dough belt folding system, also known as the pastry opening system in the industry

-Gauging roller

The width and thickness of the dough belt that has been extended through multiple rolling passes are determined according to the needs of the rolling dough. The final product thickness required by the travel is determined according to the production capacity requirements. The width of the rolling dough is determined according to the production capacity requirements. We can provide 680-1280 mm equipment width to meet the production capacity requirements of different customers.

-Dis-cutter

The width of the rolling dough is determined according to the production capacity requirements. And the finally dough belt width sometimes more wider than required size ,so dis-cutter will deduct this part dough according with customer’s demands

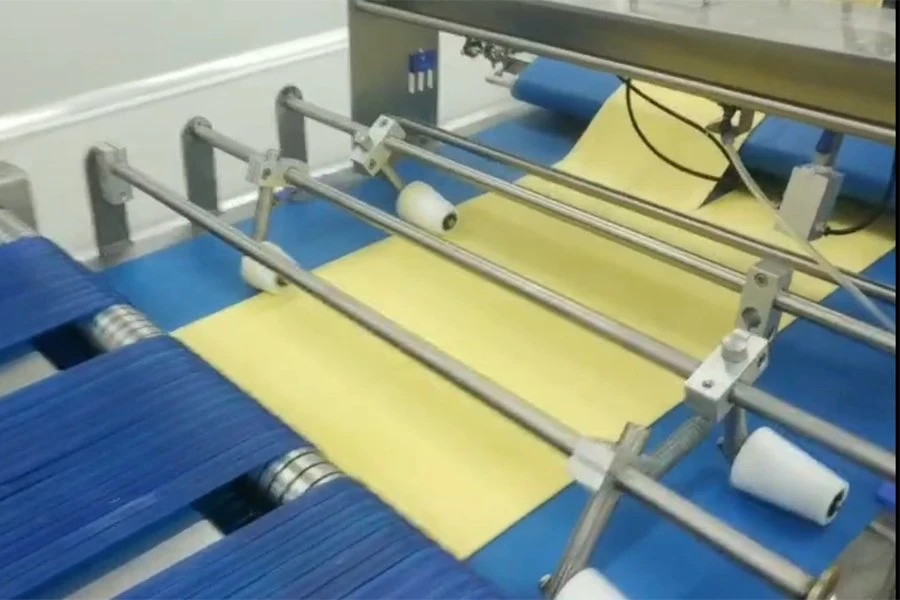

-Separator

The dough belt with uniform thickness and width is divided by several rolling cutters to prepare for the triangle cutting. The remaining dough belt after the longitudinal cutting will be collected at the recycling place and returned to the hopper for reuse.

-Rolling To Cylinder

When making ramen buns, chocolate buns, or filling roll products, use the roll mechanism

-Guillotine

Separator sheeting dough line running to Guillotine device ,been to cutted to required length ,become to Cylinder cutted dough and square puff pastry ,or oblong puff pastry .